瞻鋰電池材料開發所需之高階檢測技術成果

[ 發佈日期 ] 2024/2/29 上午 12:00:00

內容:

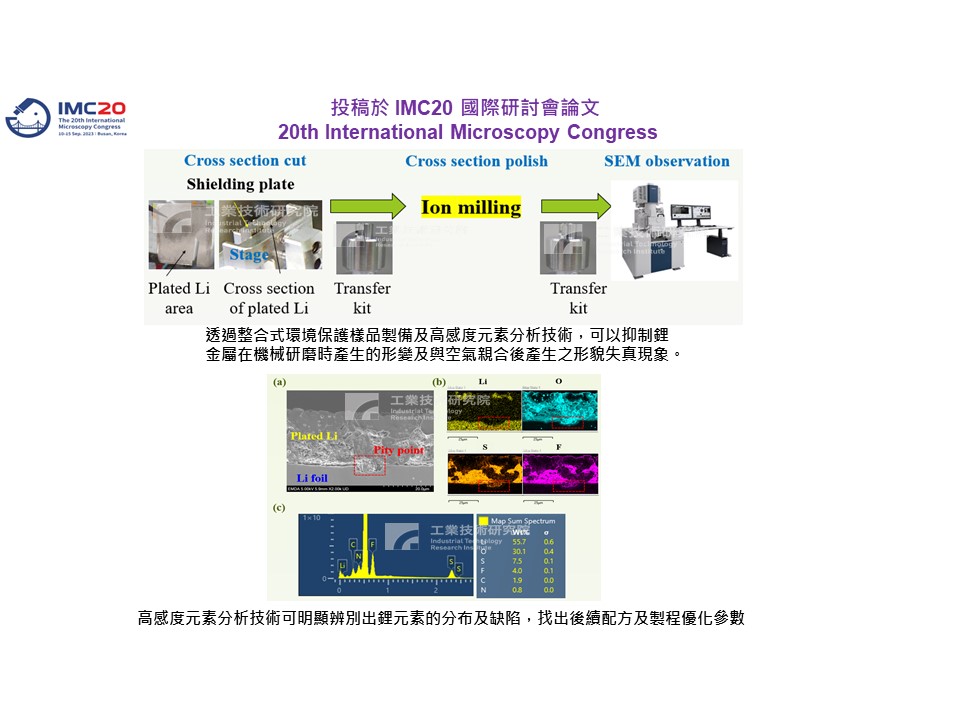

Lithium metal is an important anode material to accomplish high power application due to its high energy capacity. The safety issues such as short and explosion related with lithium dendrite growth prohibit the application of lithium metal in battery products. Therefore, investigating lithium plating microstructure is critical to evaluate the effectiveness of several dendrite growth process such as artificial solid electrolyte interphase coating and electrolyte formulation modification. Unfortunately, lithium metal is easily oxidized and sensitive to mechanical stress. Conventional sample preparation methods such as polish/grind by aqueous slurry could cause problematic cross section morphology, for instance, smeared interface, layer delamination, dendrite oxidation. Here, we demonstrate the process flow through combining cryo ion miller, environmental protection and lithium detection energy-dispersive X-ray spectroscopy (EDS) to reveal pristine lithium plating microstructure.

鋰金屬具有最低的標準電位以及高的電容量,因此可獲得優異的能量密度,成為具可實現高功率應用的重要負極材料。 與鋰枝晶生長相關的短路、爆炸等安全問題阻礙了鋰金屬在電池產品中的應用。 因此,研究鋰層微觀結構對於評估固態電解質界面和電解質配方等幾種枝晶生長過程的有效性至關重要。 不幸的是,鋰金屬很容易被氧化並且對機械應力敏感,傳統的樣品製備方法(水系拋光/研磨)會導致橫截面型態出現問題,例如界面髒污、分層、枝晶氧化等。 因此我們開發前瞻鋰電池檢測技術,整合低溫離子束研磨、環境保護和鋰元素能量色散 X 射線光譜 (EDS) 分析,以達到無失真的鋰層微觀結構與成分分布分析。

附件: